On the trail of waste

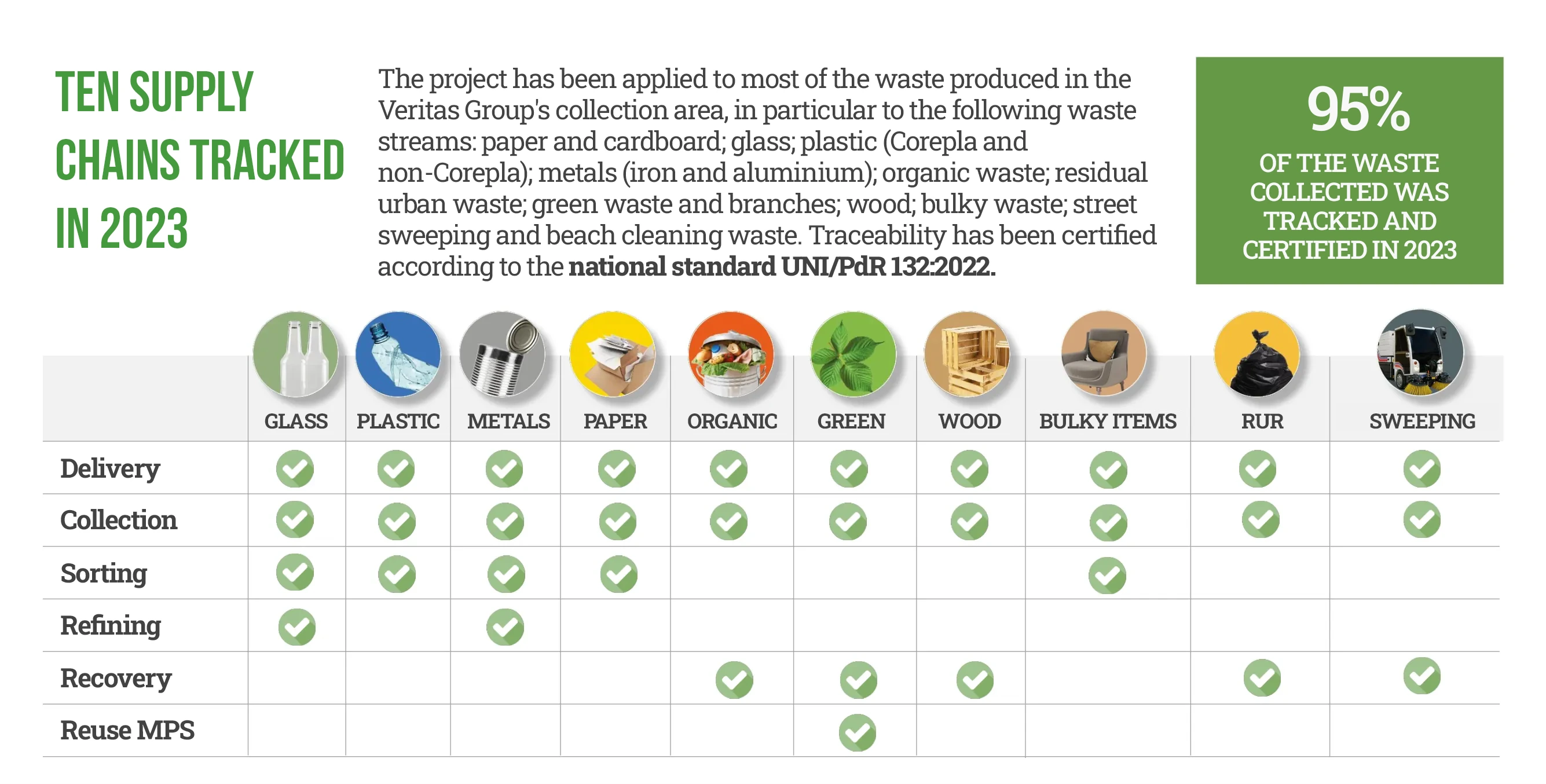

To ensure maximum transparency, Veritas has traced the waste supply chains. This means that all waste and materials collected separately are tracked, monitored, measured, and recorded from the moment of delivery to their treatment and reuse.

Why trace waste?

- To evaluate the overall effectiveness of the collection system;

- to make the waste treatment process transparent, starting from the daily commitment of citizens;

- to assess the actual recovery of separated waste and the energy required to treat it;

- to perform management control of the various stages of the supply chain;

- to set rules pending a reference standard.

How is the waste produced in the Veritas territory managed?

In the Fusina logistics area there is a platform where the waste collected in the Veritas territory is transported. Here Eco+Eco, a company of the Group, controlled by Veritas, transforms dry waste into CSS (secondary solid fuel), from which electricity is generated.

Just a few hundred meters away, glass-plastic-can sorting takes place. Also within the Ecodistrict, Eco+Eco manages a plant for sorting glass, plastic, and cans, and another for bulky waste recovery.

Paper and cardboard, WEEE (waste electrical and electronic equipment), toxic and hazardous waste, and other types (tires, used oil, batteries and cells, medicines, clothes, wood) are sent to other plants for treatment.

TRACED WASTE

The data were processed during 2024 and refer to the period from January 1, 2023, to December 31, 2023.

Waste traceability

2024

2023

2021

2020